Cordoba3

FORMAT 52 x 120 cm

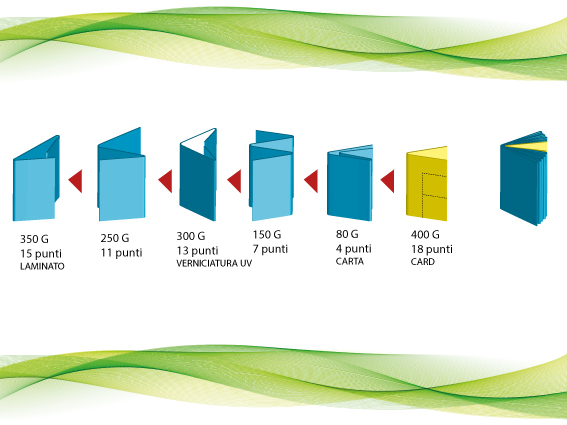

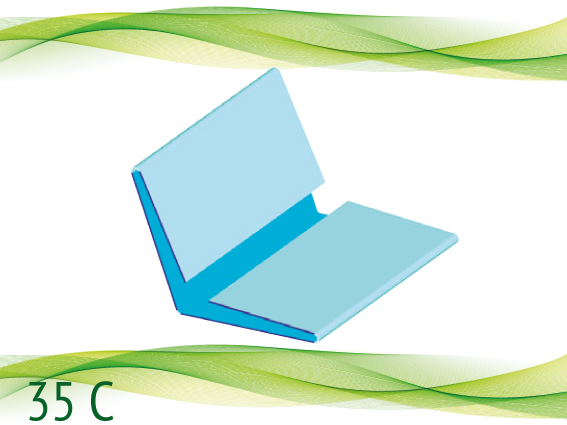

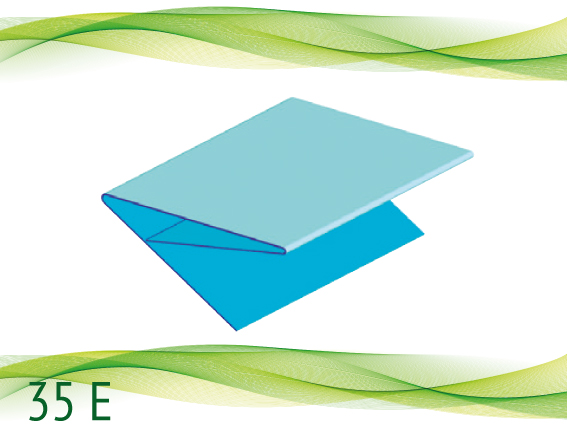

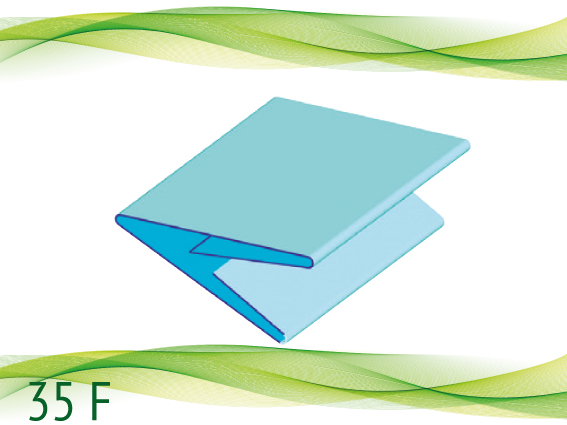

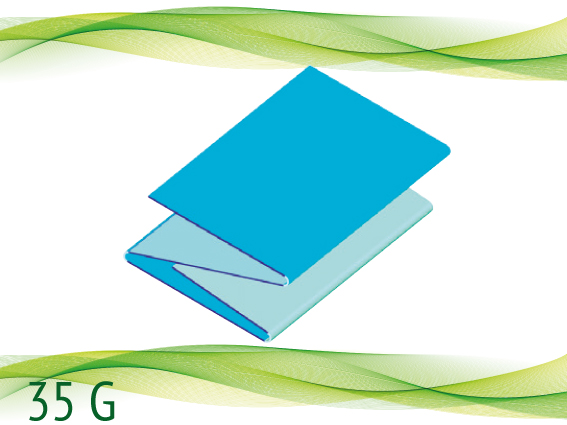

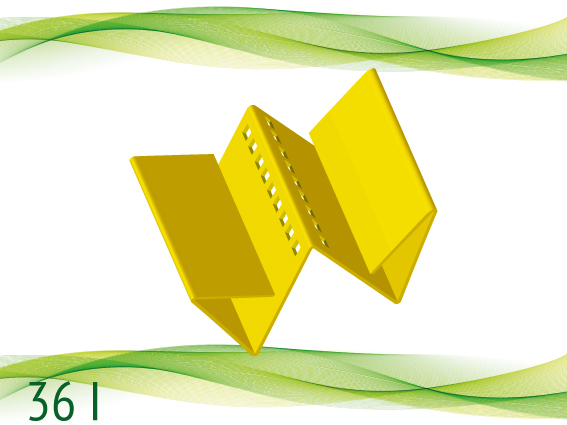

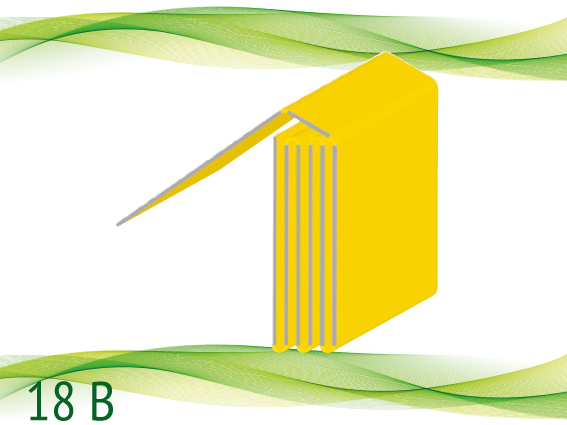

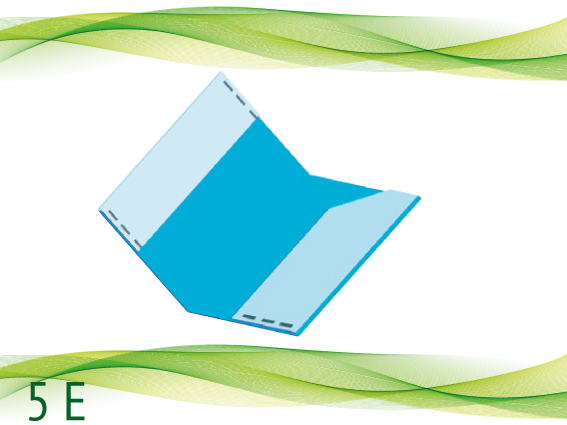

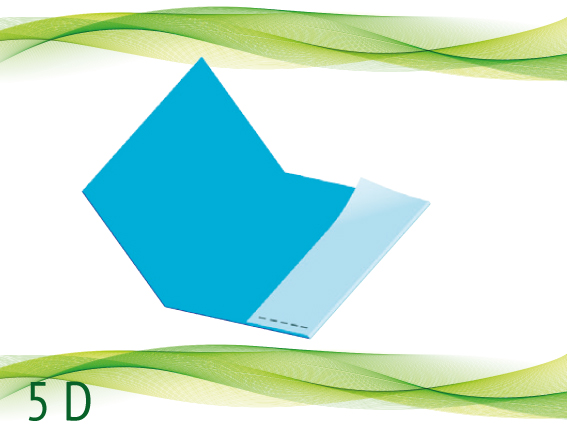

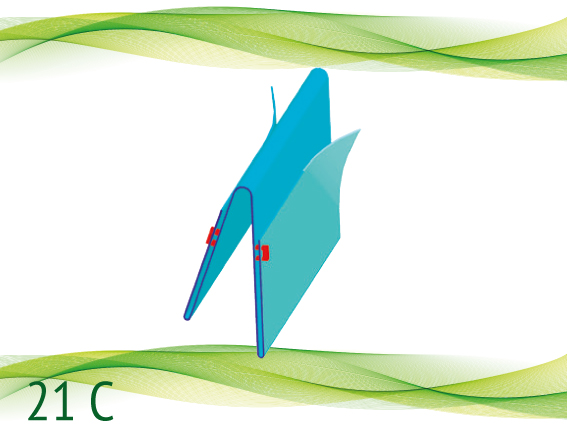

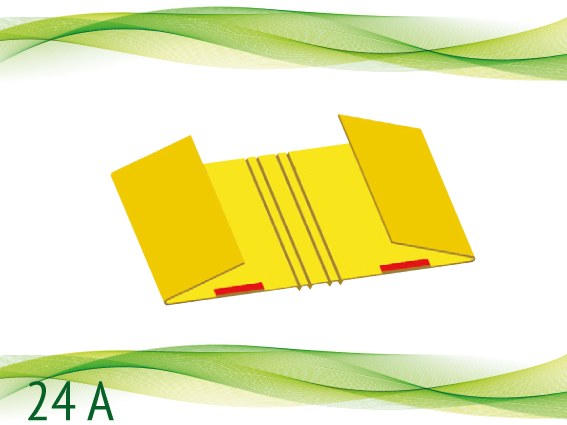

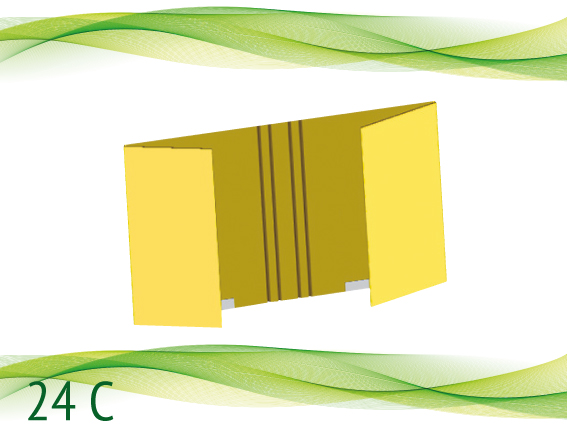

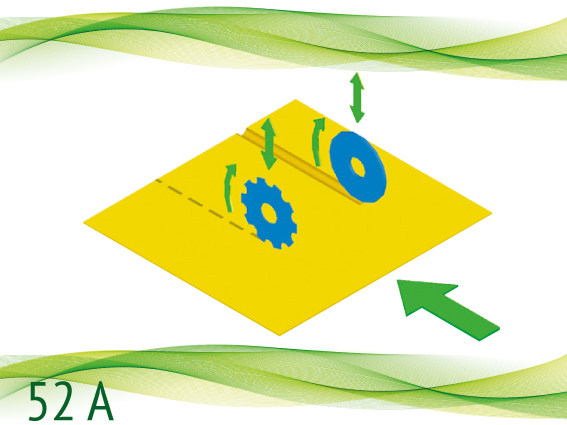

For creasing paper and cardboard (80~600 g) in the production of covers with single and double flaps, gate folds, tri-fold and Z-fold leaflets, saddle stitched covers, brochures, pocket folders, double adhesive tape application, folders, and so on…

- Max. paper size: 52 x 120 cm

- Min. paper size: 15 x 20 cm

- Max. speed (A4 size, 1 creasing line): 14000 pcs/h

- Creasing stock range: 80 – 600 g

- Folding stock range: 140 – 600 g

- 2° die-creasing / die perforation group (head).

- Programming of longitudinal and cross perforations.

- Hot melt gluing system.

- Double-adhesive tape application.

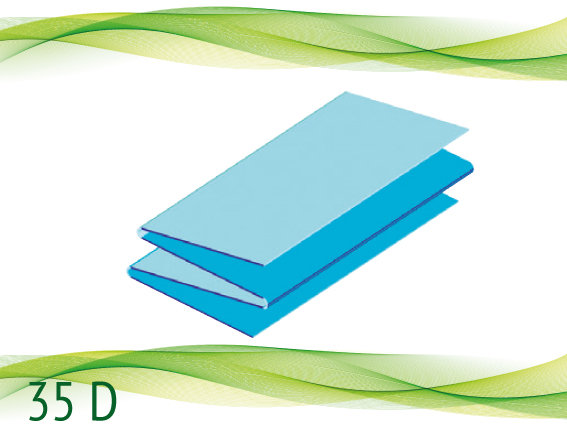

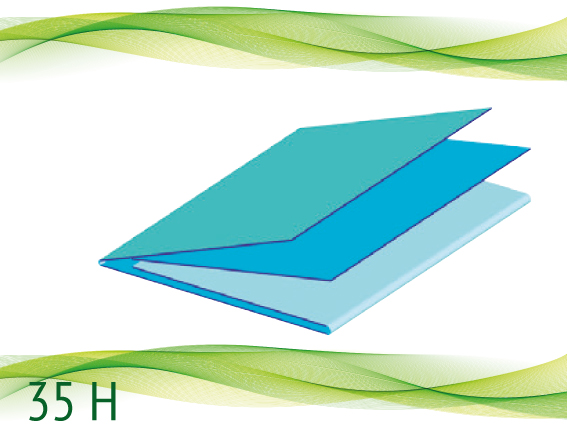

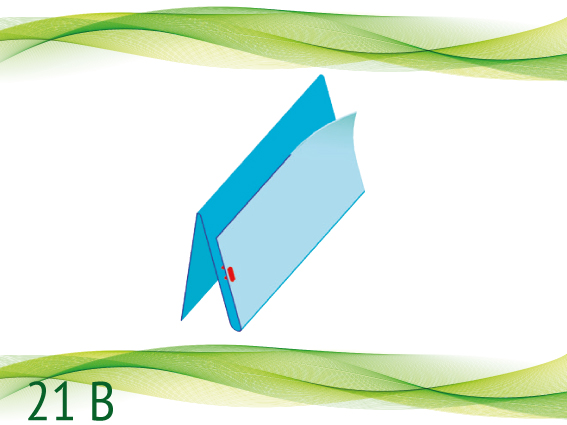

- Gate fold.

- Buckle’s reducer, to fold low grammage paper.

- Folding ploughs for folders and integral covers (folding and gluing only).

- Shingle feeder (rotary-like) for a continuous feeding.

- Continuous feeding for the second step in the production of integral covers.

FEEDER:

- Pile feeder with vacuum belt and automatic device for cleaning the valve. It is equipped with air blasts for spacing the sheets, when there is no suction.

LAY REGISTER TABLE:

- Lay register table with round belts, in lower and upper position, anti-scratching for UV-coated and laminated sheets.

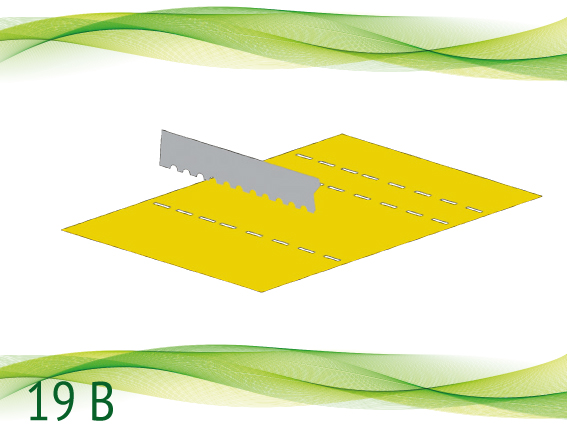

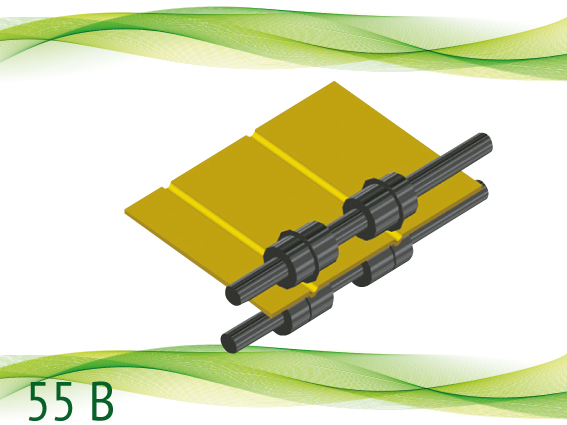

CREASING:

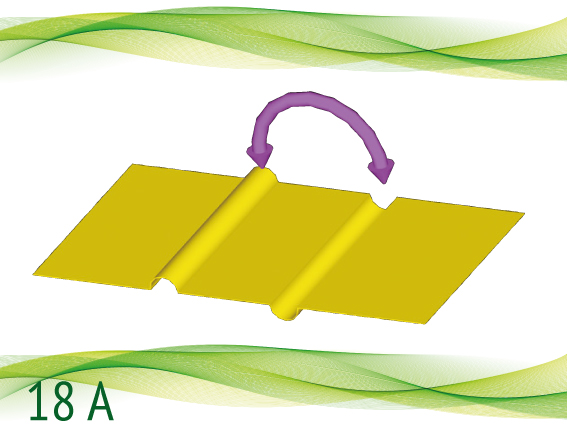

- Noiseless die creasing (new model), with a 51 cm long creasing blade.

- Easily replaceable matrixes, thanks to a bayonet system that enables quick changes in creasing width (Optimum creasing with all paper grammages).

- Digital programmer to set creasing and gluing positions.

- Copy counter.

- Output counter.

- Programmable copy divider.

FOLDING GROUP:

- N° 2 parallel folds with a “V-shaped” buckle, to fold medium to high paper grammages, without ruining the product.

- Alza tas – Handles to allow only one operator to open pocket buckles.

- Pocket buckles with built in deflectors.

- Folding cylinders with 7 cm diameter.

DELIVERY:

- SC 10 Shingle delivery with single belt and pressing roller

The Cordoba range adopts a matrix system to crease substrates prior to folding.

Cordoba incorporates a traditional folding section with a knife and matrix creasing unit. The folding group has bigger rollers and modified buckles to avoid crackings and curls when folding heavy stocks.

Attachments can be added e.g.: perforating and gluing optionals together with folding ploughs can be added to produce presentation folders.

The machine can crease from 80 to 600 g and fold from 140 to 600 g. When folding light weight stocks a standard folding unit can be added.