SAB 100

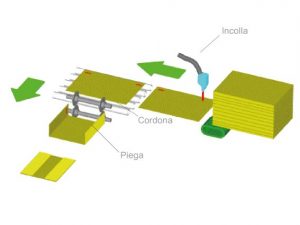

First step:

Covers are fed by a belt feeder or a pile feeder. Then they are scored on the spine in parallel with the foldable flap lines. Gluing and folding of the flap lines take place immediately after.

- Max. format: 100 x 100 cm

- Min. Format: 8 x 8 cm

- Max. speed: 120 m/min

- Max. copies/hour: 18000

- Grammage: 150 to 500 g

Second step:

Covers are fed by a belt feeder or manually (it is not possible to use the pile feeder), then the last two scoring lines and folds are made.

SAB100 machine has been designed to automatically produce book covers. SAB100 is available in different models. It is possible to produce all kinds of book covers.

The digital system allows a total and simultaneous logical control of all speeds. For example, if the folding gluing group requires a low speed, the feeder must run at a higher speed. These proportions are maintained automatically.

In addition there is also a button for the slow running of the machines back and forth, without the use of manual handwheels.

The length of the incoming / outgoing sheets and the quantity being processed are controlled automatically. In the event that a sheet does not finish its working cycle, the machine stops, displaying the jamming point, and allows, if possible, the completion of the subsequent operations.

The simplicity of the digital system allows to work also with single machines, or to connect the system to other types of machines (2nd group of SAB, CORDOBA, Metro) or to add other attachments for special jobs; obviously everything is always displayed in and controlled from the touch screen panel.

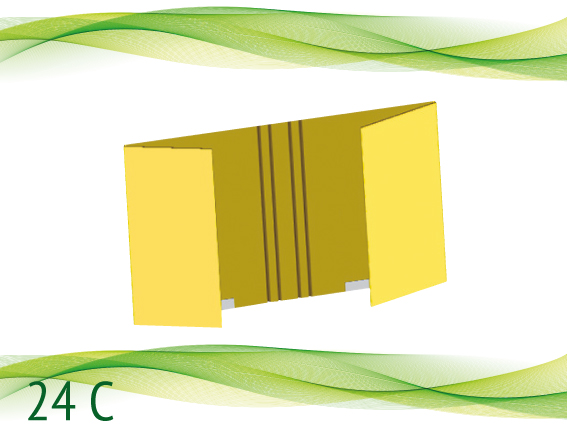

Sab100 can be upgraded, even at a later stage, by adding a second group at 90°, thus transforming the machine into a SAB100C for the production of covers in a single step.

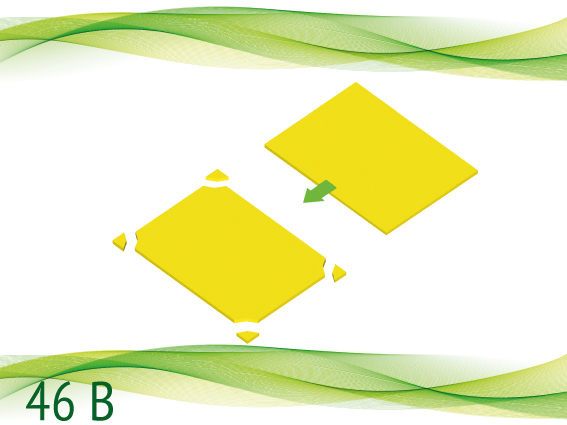

CORNER CUTTING

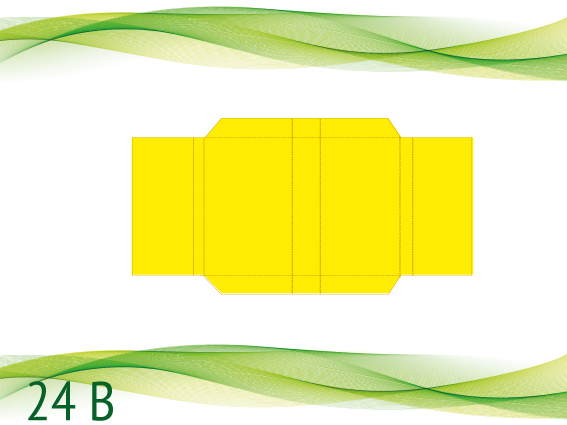

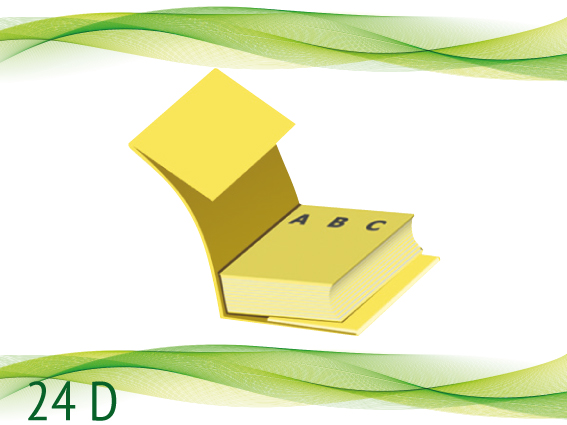

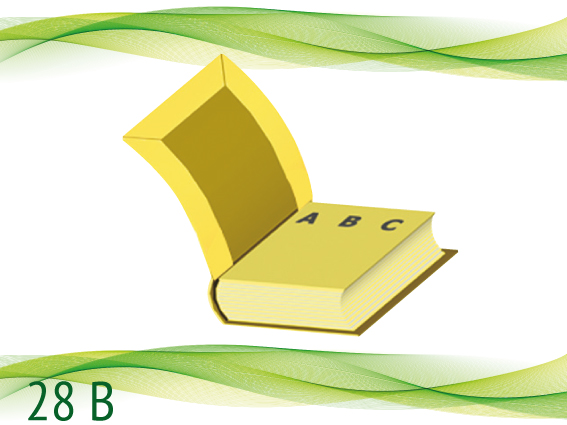

COVERS WITH FLAPS

for perfect bound books:

flaps are kept closed thanks to a narrow line of glue, placed at the foot of the cover. In this way, the next operations on the perfect binding machine can be done at a normal production rate, as problems on the cover feeder, on the clamps, on the belts and on the three-knife trimmer are avoided. Later, trimming will eliminate the glued part.

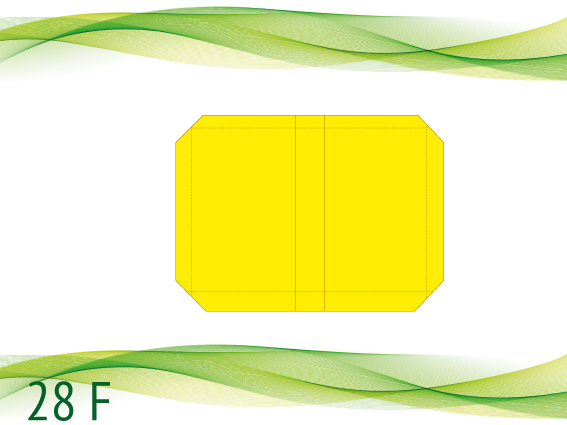

PREPARATION

OF INTEGRAL COVERS:

Before starting the production, the four corners of the covers must be cut with the appropriate shape, using either an off-line corner cutting device or the

BELT FEEDER:

Covers are intaken from a lower vacuum belt. In order to avoid friction, the vacuum device becomes an airblast device, preventing the contact of the moving belt with the next sheets.

ANTISTATIC DEVICE:

The air inside the airblasts can be transformed into antistatic air, to allow processing paper laminated on both sides. The vacuum pump, in addition, stops working if the feeder is not running for 20”.

SIDE LAY:

The registering roller table allows to infeed the jobs either inline or crosswise.

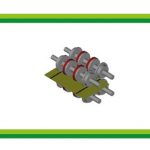

SCORING

Three pairs of scoring rollers allow the most varied combinations of scoring, cutting and perforation, and a correct and different balance of pressures.

MOVABLE CONTROL PANEL WITH TOUCH SCREEN:

All dimensions, from speed to gluing lines, can be easily input. The number of processed copies is displayed, and the number of copies per batch can be programmed, adjusting a separating space between the batches coming out in the delivery. Jam points, the position of the buttons and/or open safeguards are also displayed.

GLUING

The hotmelt gluing heads can be placed on the feeder or on the folding group. They are equipped with a bayonet connection, and can be removed easily for maintenance.

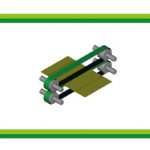

TRANSPORTATION IN THE FOLDING GROUP:

The group is equipped with upper and lower motor driven belts, that allow a safe grip and high speed.

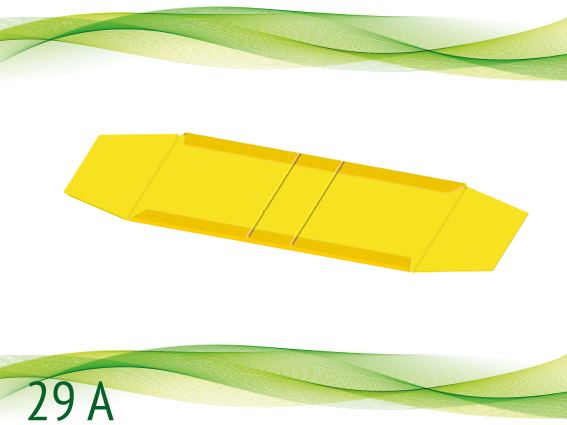

FOLDING:

Two kind of ploughs can be used: the one with wheels to fold flaps, and the one with a plate for integral covers. Ploughs and counter ploughs are assembled on a single support, for fast size changeovers.