FLY CUT

IN-LINE CORNER CUTTING

This system is made of two cutting groups, each one with its own motor driven cylinder. Two shaped blades are placed on the cylinder. When paper moves forward, the cyclinder starts turning and the first blade reaches the front edge of the cover.

Once cut, the cylinder stops and the cover keeps on moving forward. When the back edge of the cover is reached, the cylinder starts turning again with a perfect syncronization and carries out the second cut.

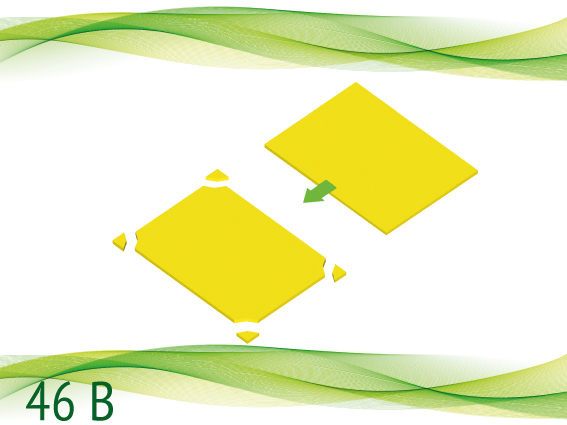

This device is placed on the central creasing rollers. It cuts the four corners of the integral covers on the move (without stopping the paper) and in line (at the same time of the creasing, gluing and folding operations).

The preparation or the cutting of the four corners of integral covers is always done outside the machine, using manual corner cutting machines equipped with special shaped cutting tools.

Preparation time is generally the same of the entire process of the cover, and the quality of dimensions is not homogeneous.

FLY CUT cuts this cost and guarantees the perfect and consistent quality of the covers.

The shaped blades are made of an adhesive metal die cutting form. It is possible to have customized shapes.