SPEED APPROX.: 6.000 C/H (100 PC/MIN)

TOTAL FOOTPRINT APPROX.: 6 X 3.5 MT.

TOTAL POWER APPROX.: KW 17

CONSTRUCTION OF MECHANICAL PARTS: ITALY

ASSEMBLY AND TESTING: PETRATTO FACTORY IN TURIN

ELECTRIC COMPONENTS: EUROPE

SOFTWARE DEVELOPED AND OWNED BY PETRATTO

CE CERTIFICATION – MANUALS IN ENGLISH

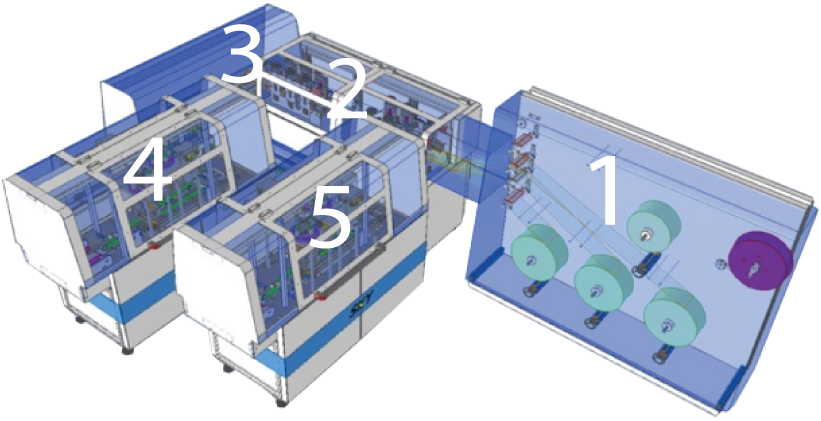

- Machine for the feeding of the coils (1)

- Machine for the coupling, ultrasonic welding, of the various layers and cutting the mask to size (2)

- 90° connecting line (3)

- Two machines for the welding of the side straps (ear strap) (4/5)

- Protections that prevent access during operation according to CE standard.

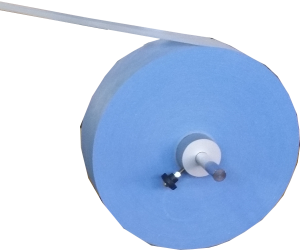

Type of materials: Melt blown fabric

Width: 17.5 cm

Gr. 20-25

Type of materials: Melt blown fabric

Width: 17.5 cm

Gr. 20-25

Type of materials: Melt blown fabric

Width: 19.5 cm

Gr. 20-25

Type of materials:

Width: 3 mm

Thickness: 0.7 mm

Length: 95 mm

Type of materials:

Diameter: 2.5 mm

Length: 20 cm

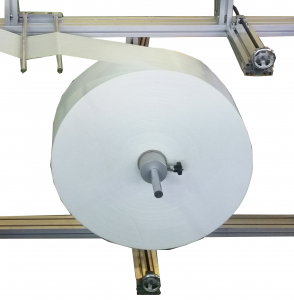

Width: 180 / 185 / 190 / 195 mm

Internal diameter: 35-85 mm

External diameter: 600-800 mm

Coil feeding group (1)

- 4 coil holder for layered materials.

- 1 coil holder for nose shape support.

Security protections – CE STANDARD

- PROTECTIONS prevent access to dangerous areas of the machine.

- All the moving parts of the machines which could constitute a danger are protected by fixed or movable guards locked to prevent accidental contact and avoid damage.

Coupling – welding -cutting group (2)

- Coupling of material layers.

- Inserting the nose shape support, with the possibility of adjusting the length of the insert.

- Ultrasonic welding, via sonotrodes, longitudinal edges (long side of the mask).

- Mechanical folding (concertina type).

- Ultrasonic welding, via sonotrodes, transversal edges ( short side of the mask).

- Cut to size of the mask.

- Deposit on sectoral channel for deflect 90 ° the single mask.

Sorting group with 3 outputs (3)

- Motorized “channel” with sectors.

- 2 alternating pneumatic pushers for sending the masks to the supply channels for the next step.

- 3rd exit for emergency (if one machine for ear strap is stopped, the other one continues the operation).

This Solution allows a compact footprint of the machine.

n°2 line to cut / form / weld the ear strap (4-5)

- Channel / belt reception of single masks.

- Ear strap feeding.

- Legth cutting with preparation and insertion.

- Ultrasonic welding, using sonotrodes (it is used to melt the strap on the inside of both ends of the mask body).

- Single mask collection on belt.

Via Don Minzoni, 1

10040 Pianezza – Turin – Italy

Opening Time: Mon-Fri

8.30 am – 12.30 pm / 1.30 – 5.30 pm

petratto@petratto.com